Tires are more than mere rubber. Today's car tires are carefully constructed with multiple layers of various rubber compounds, nylon, steel, and polyester, among other materials. These various components play key roles in defining the tire's ride, wear, and other characteristics. This page will explain the different parts of a tire, the purpose of each part, and how these parts interact to make the tire function as a whole.

Treads

The tread is the circumferential rubber area on a tire that comes in contact with the road. Treads are responsible for providing traction and road grip. The tread pattern, or the grooves and sipes on the tread area, serves to enhance the tire's handling capabilities. For instance, many tread patterns have wide grooves that run circumferentially around the tire that help to drain water and prevent hydroplaning on wet roads, while the tread "ribs" between each groove help to improve dry handling. All-terrain tires often have large, wide tread voids that provide grip on mud and other offroad terrain.

A tire's tread is made from a compound of natural and synthetic rubbers that is flexible enough to provide traction, yet also strong enough to resist abrasion and sudden wear. Tread compounds may vary depending on the tire's purpose. Carbon black, which gives tires their standard black color, is used as a filler that reinforces the rubber compound and enhances its durability. Many tires today also contain silica as a reinforcing filler, as silica reduces tire rolling resistance while also improving tread wear. Certain rubber compounds also adhere better to wet surfaces, improving wet traction at lower speeds.

Sidewalls

A tire's sidewall protects the body plies from damage. They use specialized rubber compounds that resist cuts, tears, and abrasions, as well as damage from exposure to oxygen or ozone. The sidewall also displays various markings that indicate vital information about the tire's specifications, including its width, profile, speed ratings, and maximum air pressure, among others.

Sidewalls have a major influence on the tire's ride quality and handling. Taller sidewall profiles are a little more flexible, so they improve ride comfort by cushioning shocks and vibrations from the road. Shorter sidewalls are a little stiffer, so they improve handling response by efficiently transmitting steering input from rim to tread. Light truck tires and trailer tires often have thicker sidewalls than passenger tires, making them less suceptible to swaying when carrying heavier loads at the cost of comfort.

Beads

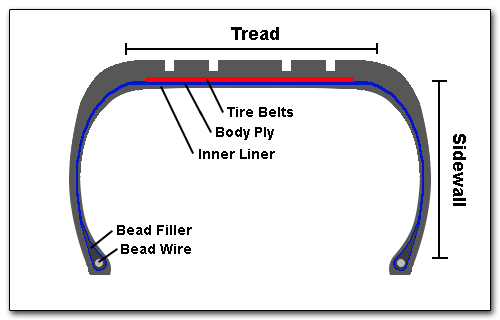

The tire beads are the edges of the tire which keep it seated on the wheel. Each bead is an elastic band that runs along the tire's inside diameter, reinforced with a core of high-tension steel wires woven into a cable, contained in a layer of hard, resilient rubber. The beads are also filled with a special "bead filler" rubber compound that stabilizes the lower sidewall area to improve steering response.

When the tire is inflated, the beads hold the tire securely on the rim, preventing it from slipping. The strength of the bead wires help to determine what rim width the tire is compatible with. Some tires may have multiple bead wires for increased strength and stability.

Tire Belts

Between the tread rubber and the body plies are the tire belts. Tire belts typically consist of two layers of rubber-coated angled steel cord plies under the tread area that reinforce the tire's structure and maintains the tire's shape. These sturdy steel belts help to keep the tread area flat, providing more stable tread-to-road contact, traction, and handling response. This also encourages the treads to wear evenly all around the tire, improving the tire's mileage.

Some performance and high-end all-season tires contain a layer of nylon cord ply between the tread rubber and the tire belts, called the nylon cap. The nylon cap ply wraps circumferentially around the tire casing, preventing the steel belts from shifting or the tire's shape from deforming at higher speeds. This helps to maintain tread stability and handling response for high-speed performance driving applications.

Body Plies

The tire's main body consists of multiple layers of thin, densely-laid rubber-coated fabric cords, or body plies. Also called the tire carcass or casing plies, these body plies wrap around the beads and run across the tire casing from bead to bead. Body plies are the source of a tire's internal strength, allowing it to contain air pressure, carry loads, and resist impacts. Most tires today use polyester cord for body plies due to polyester's high tensile strength.

Virtually all passenger and light truck tires today are radial tires, indicated by a "R" in their sidewall markings. This means that the body plies run straight across the tread width at a 90-degree angle to the tire's direction of travel, as if "radiating" out from the tire's center. These body plies synergize with the tire belts to support the tire's structure. (This contrasts with older "bias-ply" tires, where the body plies ran diagonally across the tread width in an interwoven pattern, and are not supported by a belt layer.)

Radial tire construction puts more force on the tread area and less on the sidewalls. This increases tread rigidity to provide stable road contact, while also allowing the sidewalls to flex for a smoother, more comfortable ride. Since radial body plies are laid in parallel and do not rub against each other as the tire rolls, radial tires have lower rolling resistance and are more fuel-efficient than bias-ply tires. This also makes radial tires less susceptible to damage from internal heat buildup, improving their tread life and longevity.

In the past, a tire's ability to contain air pressure and carry loads was measured by counting the number of body plies, or the tire's ply rating. However, the polyester plies in today's tires have a much higher tensile strength than the cotton plies used in older tires, so most tires today only need two or three body plies.

Inner Liner

The inner liner, or the innermost rubber layer under the body plies, is responsible for containing the tire's air pressure. Modern car tires are tubeless tires, meaning that they don't contain an inflatable inner tube. Instead, a tubeless tire stays inflated by pressing the beads tightly against the rim to create an airtight seal, providing an inflatable air cavity inside the tire. The inner liner, which surrounds the tire cavity, is made from a special airtight rubber compound that prevents air from escaping the tire.